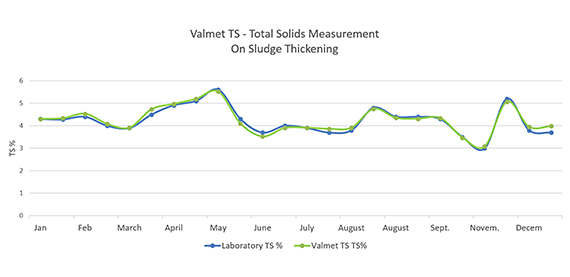

Valmet Total Solids Measurement (Valmet TS) is a reliable and accurate microwave real time measurement used to control and optimize the solids treatment process, giving operators information on the total solids 24/7. Being the most reliable and accurate measurement for wastewater applications, Valmet TS allows savings in polymer dosing, energy, and transportation.

Industrial quality for all solids treatment applications

Measurement of solids in wastewater treatment has always been a questionable proposition. Limitations in measurement accuracy along with long term reliability has been a concern to plant operators and engineers. Adding to this, one of the biggest challenges is the fact that solids treatment and disposal makes for over 30% of the wastewater treatment costs.

Valmet TS utilizes microwave technology to determine total organic and inorganic solids content in the range of 0-50%. With Valmet TS wastewater plants can achieve big savings with mass flow based controls, and further advance the environmental and public health benefits in the community. Controlling and developing the process can be enhanced through accurate and fast measurements, which improves the overall efficiency of a wastewater plant and provides crucial data for dewatering optimization.

Valmet TS sensors are also suitable for explosion-proof applications having ATEX, IECEx, and UKEX certifications.

The most accurate and reliable measurement of total solids

- Provides higher solids content in sludge

- Savings in polymer dosing

- Energy savings in pumping

- Reduced heating cost at the digester

- Increased capacity with existing plant

- Optimized biogas production

- Reduced transportation costs

- Highly efficient use of dewatering centrifuges

- Less laboratory analysis

- Maintenance-free

- Single point calibration

- Long experience and know-how in microwave technology

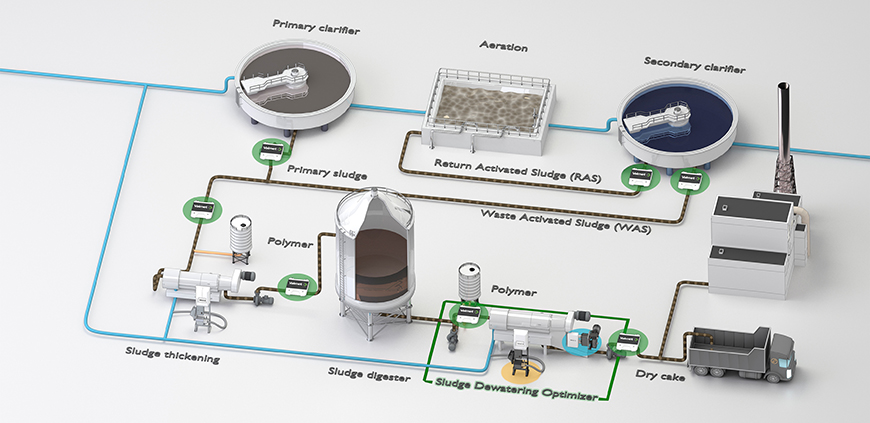

Primary clarifier pumping

- More capacity – Less water pumped to the sludge process

- No accumulation of solids in the clarifier

- Energy savings in pumping

Thickening process

- Savings with polymer dosing

Digester

- Heating energy savings

- More gas production

- EX certificated (Ex II 1/3 G Ex ib nR IIC T4 Ga/Gc)

Sludge dewatering

- Optimized polymer dosage based on massflow

- Typically savings of 20% with optimal polymer dosing

Dry cake solids amount optimization

- Less water in the dry cake

- Savings in transportation and incineration costs

Measurement

| Measuring Range | 0 - 50% TS |

| Repeatability | ± 0.01% TS |

| Sensitivity | 0.001% TS |

| Filtering | 1 - 99s |

| Microwave Power | -6...+25dBm |

Pressure Measurement

| Measuring Range | 0 - 25 bar |

| Accuracy | ± 0.1 bar |

Process Conditions

| pH range | 2.5 - 11.5 |

| Temperature | 0 ≤ T < 100°C / 32 ≤ T 212 °F |

| Vibration | max. 20 m/s², 0 - 2000Hz |

| Process Flow | min. 0.01 m/s |

| Minimum Process Pressure | Pipe must be full, pressurized and flowing |

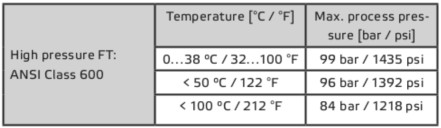

| Maximum Process Pressure | |

| Twin Blade | PN25 |

| Standard Flow Through | DIN PN16 / ANSI Class 150 / JIS 10 K |

| High Pressure Flow Through | DIN PN100 / ANSI Class600 / JIS 63 K |

|

|

Operating Environment

| Temperature | -20... +70°C(-4...+158°F) protect from direct heat sources |

| ATEX/IECEx | -10...+70°C(+14...+158°F) protect from direct heat sources |

| Housing Class | IP66 (NEMA 4X) |

| ATEX/IECEx/UKEX | Ex II 1/3 G Ex ib nR IIC T4 Ga/Gc; -10°C ≤ Tamb ≤ 70°C IECEx EESF 20.0020X; ATEX:EESF 20 ATEX 056X; CML 21 UKEX2625X |

Connections

| Operating Power, Communication | M12 sensor cable from operating terminal |

Materials, TB Sensor

| Wetted Parts | AISI 316L Ceramic; OPTION: non-stick, rubber lining or hardened |

| Sealing Rings | EPDM, FKM, PTFE |

| Process Coupling | AISI 316L |

| Mounting Clamps | AISI 304 |

| Mounting Bolts | 8.8 ZNE and AISI 316 |

Materials, FT Sensor

| Wetted Parts | AISI 316, AISI 316L, Ceramic; OPTION: non-stick or hardened |

| Sealing Rings | EPDM, FKM |

Connections

| Cable to Sensor | length 10m (33ft) |

| Operating Voltage | 90 - 260VAC/10W |

Connections to mill systems

| Analog Outputs | 2 current outputs, 4-20mA |

| HART | 12 - 36 VDC |

| Binary Inputs | 4 x 12 -28 VDC / 10mA isolated |

| Relay Outputs | 2 relay outputs, max. 250 VAC, 220 VDC/2A |

Connection Options

| USB | SW Update, Backup |

| Ethernet |

Operating Environment

| Temperature | -5...+50°C(+23...+122°F) |

| Housing Class | IP66 (NEMA 4X) |

Materials

| Housing | Aluminium Casting |

| Display Cover | Polycarbonate |

Dimensions and Weight

| w x h x d | 258 x 303 x 172 mm 10.2'' x 11.9'' x 6.8'') |

| Weight | 6.4kg (14.1lbs) |