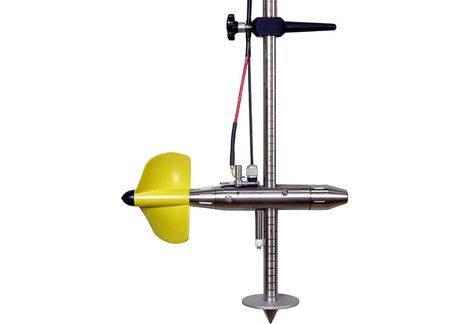

- Robust, hydrological impeller for flow measurement on a Ø 20 mm rod or on a load weight (float wings)

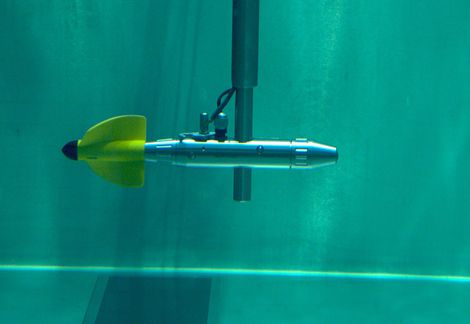

- Point measuring method (detection point velocities in the measuring verticals)

- Suitable for measurements in watercourses with low to high flow rates

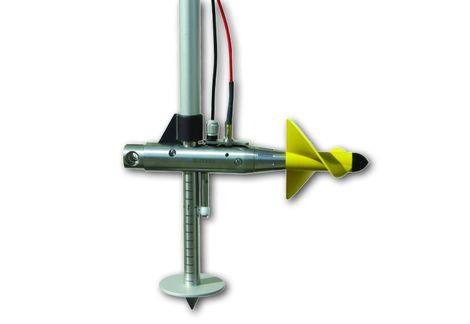

- Different wing vanes available for different applications

- Connects to Counting device Z6 or to a notebook or tablet PC HDA-Pro, operated with Software Q 3.1 and "impeller" module

Robust, accurate and effective:

Precision mechanics made in Germany. Even the most cutting-edge measurement methods for mobile flow measurement must first prove themselves against the hydrological universal current meter. The SEBA universal current meter has been used worldwide for decades and has proven itself in the most adverse conditions.

Variable:

The SEBA F1 universal current meter can be operated both on a Ø 20 mm rod as well as with a loading weight, in conjunction with a SEBA single winch type SEWII or double-acting winch SDW-ES. By default, the impeller body is fixed to the rod by means of a locking screw. Alternatively, the F1 can also be fitted on a push-over linkage to ensure a rapid vertical up and down movement. In a further variant with a flow direction fin, the universal current meter rests easily on the rod where it always exactly assumes the direction of the flow. A wide range of different impeller blades made of plastic and aluminum with 80 mm or 125 mm diameter and different pitch axial flow impellers are available, so as to optimally adapt to the respective flow conditions.

Low maintenance:

The F1 is undemanding and even during intensive use, it generates hardly any operating and maintenance costs. For highest accuracy requirements, we recommend regular calibration of the impeller blades in the measurement channel.

Last but not least:

For display and analysis of the impeller pulse, the user is spoiled for choice: between the robust SEBA Counting device Z6 or the field-proven tablet PC HDA-Pro. The latter provides the possibility to evaluate the impeller pulses directly with the proven Software Q 3.1 (incl. "impeller" module)

| Impeller | |

| Measurement Principle | Mechanical (dry reed contact) |

| Measuring Range | 0.025-10 m/s (depending on the impeller) |

| Blade Diameter | 80 mm, 125 mm |

| Blade Pitch | 125 mm, 250 mm, 500 mm, 1.000 mm |

| Material |

Anodised aluminum Glass fiber-reinforced polyamide |

| Universal Current Meter Body | |

| Material | Corrosion-resistant stainless steel |

| Dimensions | 310 mm |

| Fastening |

Locking screw (adaptable to the 20mm wing bar) Spacer for loading weight |

| Wing Bars | |

| Material | Stainless steel |

| Dimension | Ø 20 mm, 1 m |

| Scaling | dm (standard), cm without (optional) |

| Loading Weight | 5 kg/10 kg/25 kg/50 kg/100 kg |